The JOBO Juggernaut

I guess we would say the JOBO is the “photographer’s” film, (and paper), processors most people are familiar with. I even used one regularly back in the “film only” days. While a lot of my film back then was done by the lab upstairs from my studio at W. 13th St., NYC, (who is no longer there), I did employ a JOBO on many occasions with rush jobs, or if he was just backed up. I bought mine at B&H when they were still on W. 17th St. Before they became a super store and moved. And it was REALLY expensive back then. I believe it was about the same price as my new Nikon F5! Weirdly, well used ones on Ebay are almost or just as expensive now! I guess there are more film users than I thought. Yes, it was a life saver when I had to process 20-60 rolls a week, both 35mm and medium format. But now,….well I’ve pretty much returned to how I developed film when I was 18, 19 years old. I only do a couple of rolls a week, and while hand agitation is boring and tedious, it’s not the end of the world. The original JOBO processors only came out in the early 80’s. I’m sure Ansel and Henri didn’t consider it to be an obstacle in their day. And, to their credit, JOBO is still with us.

JOBO Like Film Processors

But, alas, time moves on. And almost surprisingly more film options are becoming available to us die hards, without having to always resort exclusively to the used market. B’s processor, along with AGO, eTone,….and probably others, provides various pricepoint options. Always a good thing.

When one of these options is from a “non-crowd funded” enthusiast, you can only feel admiration for the effort. Especially if the effort is successful and prone to evolutionary improvements.

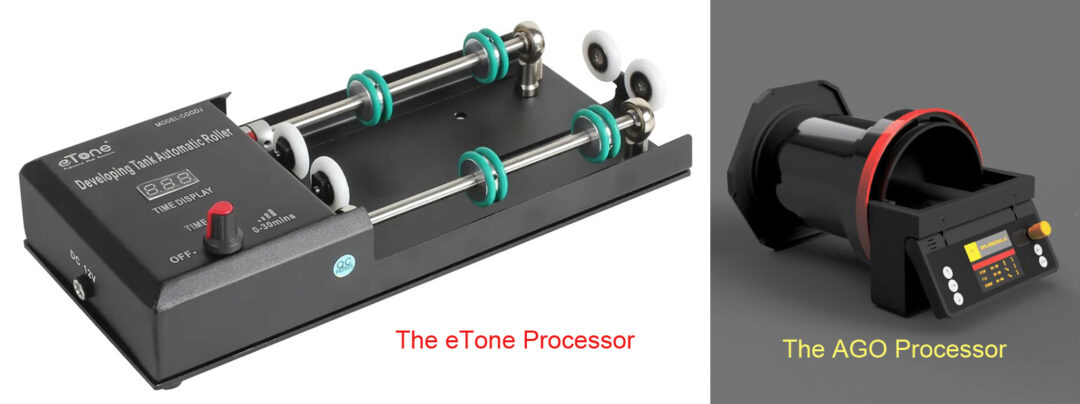

Etone and AGO-The Good, The Bad and The Ugly

Now, I haven’t personally tested the eTone processor, but I understand it to be flimsy, prone to breaking and has other issues. (not waterproof, weak motor, not true agitation, etc.) When you even get bad reviews on Amazon,….well, I’ll let you come to your own conclusions. But at a price that barely exceeds $100, I suppose it’s to be expected, and may still be all you need. The AGO is much more advanced and precise, and the various modes and digital readouts blatantly reveal that. But again, every photographer has different needs and workflows. And at a price of around $469 USD, you have to weigh real day to day advantages. Actually, if you compare that to JOBO, all these choices are quite cheap. I haven’t had a JOBO for decades, but it was expensive. And is still so,…even used on Ebay.

And More?

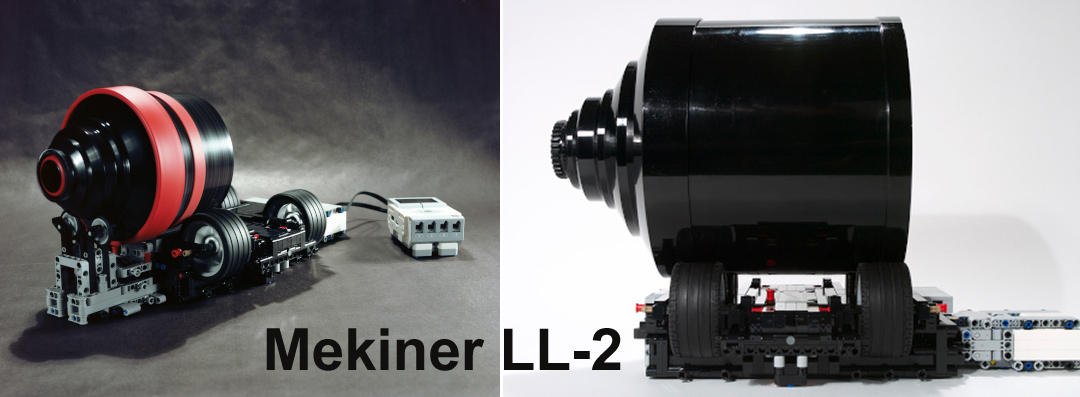

I guess I’d be considered to be derelict in my writings to not at least mention the Mekiner LL-2. But that was only because I was limiting my story to more wallet friendly solutions. However, if a film and print processor for all formats, (35mm, 120/220, 4×5, 8×10, and Ultra Large Format up to 20×24), is a requirement, then the Mekiner LL-2 may be your only go to. (other than JOBO)

In Benoît Barbé’s Own Words…

I had developed this machine very quickly since I was mostly home due to “you know what”! So I had plenty of time to spend on it. I was happy with the machine and went on buying a few thousands of dollars of parts and started production in parallel of my personal testing plus my two beta testers giving me feedback.

That proved to be a mistake…. the machine worked properly and results were ok but I realized that there is more to it than just turn one way and the other… and that bugged me! After this extensive testing, I had learned many things about what happens inside a tank in rotation. The TR, (original model), worked fine but I knew I could now make an even better machine.

By the end of the summer, a very hard question came up: what should I do? Build this machine and sell it or scrap it to make it into a better machine?… As you can guess I chose the latter. I bit the bullet and went back to the drawing board… By that time I was back at work full time so between work and family time, the design took a good while. Add another round of testing, and here we are many months later….

Here are the things I’ve learned, hopefully this will explain and make sense of my new design decisions-

What was good to keep: (or add)

- General form factor was good, compact and practical, so it did not change much on the outside…

- The wobble wheels were proven to soften hard flow as I intended them to do.

- Slow RPM is best!

- The Penguin!!

What was NOT good to keep:

- Variable speed is unnecessary and a problem for results repeatability.

- Equal rotation both ways is important to even out the liquid flows.

The “TR” was designed for speed and that was also a mistake! So many people had asked me why my original processor turned so slow, I guess because other machines are fast, that I was convinced it was the way to go. The 10-12rpm of my original machine was actually a much better speed than the 60rpm the “TR” could do. Here is the reasoning behind what I’m saying: All reels have different shapes/geometries; those geometries are most of the time in the way of the liquid and will create hard accelerated flows behind them. (Think of a rock in the middle of the river). Those flows, with the wrong circumstances, will create overdevelopment marks. You can’t avoid it, but at slow rpm, those will have less effects. This is why B’s large format reels are very minimalistic, it’s meant to reduce geometry in the liquid’s way to its minimum. To help get better and softer flows, I had designed a special “wobble wheels” extension for my original machine that you will find now integrated into my new processor. The new B’s processor comes with two sets of interchangeable wheels: the circulars and the wobbles.

Another innovation added to the machine is the new “pulsed Rotation” program. This program makes the tank go thru short acceleration and deceleration cycles while doing its 2 turns one way and the other. Avoiding a constant speed helps smooth out those flow around the geometry. I’m pretty proud of this one, it proved itself well and in combination with the wobble wheels it provides the best evenness you can get with this type of machine. This is why B’s processor now have only three programs: Pulsed, slow (~10rpm) and fast (~38rpm). At first, I was trying to make this machine in a simple way, using off the shelves electronic boards. This was also a mistake and I lost lots of time trying different combinations. Everything pointed to just make it Arduino based so it can move any way I want and that’s what I did. It allowed for a lot of flexibility to add sensors and for the future upgradability of the firmware running the machine! Any time I tune it you will be able to get the benefits of it, just plug the machine on your computer and upload the new firmware! It also allowed to use a very good motor driver witch provides good torque even at slow speed.

The “TR” prototype was hard to set the proper times for equal rotation. So I looked into a system that would insure the tank always turns the same amount both ways. I came up with a new contactless system using a magnetic band on the tank. That band is simply held with a rubber band. Baked into the programing is a routine that also detects the tank and magnet band position so it can re-synchronize itself if its position was lost or if the tank was set on the processor in the wrong position. Like that the tank always change its rotation at the exact same spot. Since the detection is contactless, there is nothing here to break compared to a mechanical switch.

Not something directly linked to the machine but more about the Paterson tanks. During my 4×5 testing, something evaded me for a while, one batch would be perfect and the next one was a disaster! I realized that the problem always happened when my reel was only half loaded, that led me to understand the unbalanced load could freely rotate at the direction change since the Paterson tank column is not linked to the tank and can spin independently. So comes the “Penguin”! This is a simple piece I designed to go at the bottom of the column, it just frictions in and grab onto the three prongs at the bottom of the Paterson Tank. It’s flat and thin so it does not get in the way of the chemistry coming in and the friction is enough to avoid any shift.

Here are the new specs:

- Genuine Arduino Nano (no crappy clones here 😉

- High efficiency motor driver for torque (a full 8 reel Paterson turns like a charm)

- Now runs on 12V for better more stable power

- Touchless rotation switch (equal rotation even if the tank slips on the wet wheels)

- Light indicator to show if the magnet band is properly triggering the switch

- Interchangeable smooth and wobble wheels

- 3 programs for perfect repeatability

- Paterson column linkage, aka the “Penguin”

- Tank position automatic detection

- Future proof. Front hatch allows access to USB plug to upgrade the programming.

- Splash proof

In Essence…

…the B’s Processor is a well built machine. While the body is 3D printed, the actual internals are fabricated from metal, and the gears/wheels are molded plastic with actual rubber gaskets. At $165 USD, B’s Processor far surpasses the abilities and (supposed) reliability of the eTone, while approaching the more than capable AGO,…minus all the digital fluff. Or you can spend $0 and just agitate by hand. Not everyone is as easily bored as me.